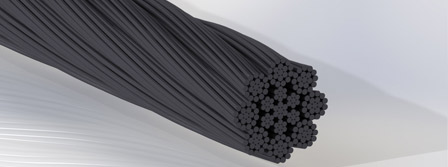

Tungsten wire ropes and strands

Tungsten wire ropes and strands from Carl Stahl Technocables.

In our rope factory we produce wire ropes and strands from tungsten wire. With our high-quality tungsten wire ropes and strands, you can count on particularly high load-bearing capacity and durability. They are ideal for use in demanding applications where absolute reliability is essential. As a renowned manufacturer of ropes and strands, we also offer you a high degree of flexibility in designing your individual solution.

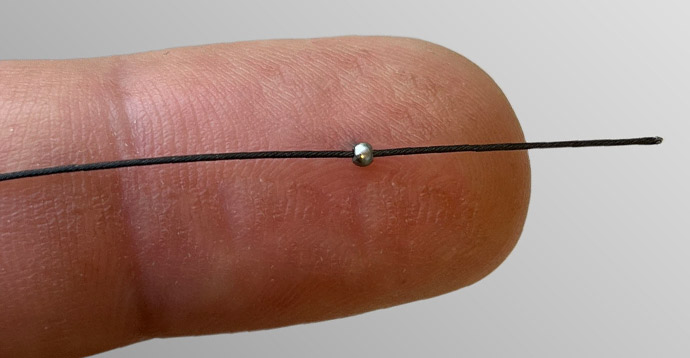

Our tungsten ropes and strands are available in a variety of rope constructions and diameters to suit the particular requirements of your application. The material of tungsten ropes is exclusively pure tungsten wire. Unlike, for example, our e-rope brand current conducting ropes, which are made of steel or stainless steel and copper wires. In addition, they can be made up for installation like conventional steel or stainless steel wire ropes, e.g. with a pressed-on ball.

Wire ropes made of other materials:

stainless steelgalvanized steelcopperNitinolwire rope information

Tungsten strand 1 x 7

| Material: | Tungsten |

| Nominal-ø in mm: | 0,075 - 0,24 mm |

| Weight in kg/1000m: | 0,07 - 0,68 kg |

| Minimum breaking force in N: | 11 - 110 N |

| Outer-ø in mm (coated): | - |

| Treatment: | swaged |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,075 | 11 | 0,070 | schwarz | LI000468 |

| 0,215 | 86 | 0,530 | schwarz | LI000464 |

| 0,240 | 110 | 0,680 | schwarz | LI000466 |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,200 | 65 | 0,500 | schwarz | LI000465 |

| 0,220 | 85 | 0,610 | schwarz | on request |

Tungsten strand 1 x 19

| Material: | Tungsten |

| Nominal-ø in mm: | 0,125 - 0,38 mm |

| Weight in kg/1000m: | 0,18 - 1,63 kg |

| Minimum breaking force in N: | 29,5 - 260 N |

| Outer-ø in mm (coated): | - |

| Treatment: | - |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,125 | 29,5 | 0,180 | schwarz | LI000471 |

| 0,350 | 230 | 1,430 | schwarz | on request |

| 0,380 | 260 | 1,630 | schwarz | on request |

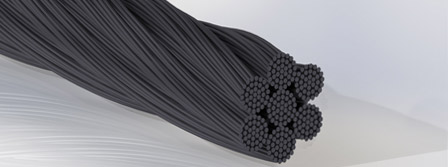

Tungsten wire rope 6 x 7

| Material: | Tungsten |

| Nominal-ø in mm: | 0,20 - 0,65 mm |

| Weight in kg/1000m: | 0,45 - 3,8 kg |

| Minimum breaking force in N: | 65 - 570 N |

| Outer-ø in mm (coated): | - |

| Treatment: | swaged |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,220 | 72 | 0,470 | schwarz | SE000659 |

| 0,650 | 570 | 3,800 | schwarz | on request |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,200 | 65 | 0,450 | schwarz | on request |

Tungsten wire rope 8 x 19 + 7 x 7

| Material: | Tungsten |

| Nominal-ø in mm: | 0,45 |

| Weight in kg/1000m: | 1,85 |

| Minimum breaking force in N: | 285 N |

| Outer-ø in mm (coated): | - |

| Treatment: | swaged |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,450 | 285 | 1,850 | schwarz | SE000670 |

Tungsten wire rope 6 x 37

| Material: | Tungsten |

| Nominal-ø in mm: | 0,5 mm |

| Weight in kg/1000m: | 2,46 kg |

| Minimum breaking force in N: | 300 N |

| Outer-ø in mm (coated): | - |

| Treatment: | swaged |

| Nominal-ø | Minimum breaking force | Weight | Color | Item No. |

|---|---|---|---|---|

| 0,500 | 300 | 2,460 | schwarz | SE000633 |

Tungsten cable properties

Refractory metals such as tungsten have special properties compared to other metals. Tungsten offers high resistance to temperatures, chemicals and wear. It is ideal for use in high stress environments and offers a long service life under demanding conditions. Tungsten does not rust and is heavier than other metals due to its high density.

Tungsten wires, ropes and strands also have these properties.

Applications tungsten wire, rope, strand

Despite the higher material costs compared to wire ropes and strands made of steel or stainless steel, tungsten wires, strands and ropes are used in numerous applications due to their exceptional properties. E.g. aerospace, automotive, electrical engineering, manufacturing technology, fishing, musical instruments, laboratory equipment, microscopy, medical technology and also in robotics. A wide range of applications, where the versatile and reliable properties of tungsten provide optimal results.

If you have any questions about your application of tungsten strands or tungsten ropes, please contact us.

Application example tungsten wire ropes in medical technology / surgical robotics

Due to the outstanding properties of tungsten, tungsten strands and ropes are used in many areas of medical technology. From medical cable assemblies and minimally invasive surgical instruments to advanced surgical robots. Very fine strands and ropes are often required to perform high-precision functions. Here, the properties of tungsten are exploited. Thin tungsten wire ropes or strands can be used with the same breaking strength, e.g. compared to conventional stainless steel wire ropes. If there are surface requirements with regard to contamination, the surfaces can be cleaned by special cleaning processes. The high density allows the use in fluoroscopic applications, as tungsten does not transmit X-rays. In state-of-the-art surgical robots, tungsten is used in motion control systems or as a guide wire. Due to their smaller size, high tensile strength and pliability, tungsten strands and wires can be safely guided through the smallest spaces, tight curves, severe bends and the smallest pulleys. The service life is much longer than with other materials, and maintenance requirements are correspondingly lower.

Tungsten cable with pulleys - Smaller, more compact designs with a longer service life

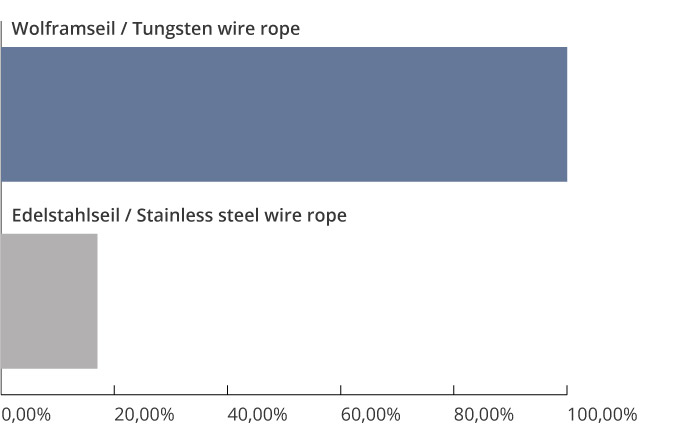

Ropes and strands from Carl Stahl Technocables made of tungsten offer many advantages. One major advantage is the resistance to bending fatigue, which is significantly higher due to the enormous strength of the tungsten wires of 3600N/mm². This special property is required for applications with pulleys. Due to the high flexural fatigue strength of tungsten cables, the service life is up to 5 times longer compared to conventional stainless steel ropes made of 1.4401/AISI316 with the same rope construction. Smaller pulleys and miniature pulleys can be used with the same rope service life.

This rope property enables smaller, more compact constructions with a longer service life.

Comparison of the service life of tungsten ropes and stainless steel ropes.

Same construction and dimensions.