Our particular strength lies in the development and production of individual rope solutions in the fine rope range from 0.09 to 8.00 mm. Many years of experience as a traditional rope manufacturer, experienced developers and complete processing from inquiry to delivery at our headquarters unite all competencies under one roof and enable us to find the right solution even for special requirements.

Strands and ropes are manufactured from stainless steel, steel, nitinol, copper or tungsten wires in our rope factory in Germany. If required, we also offer ropes and strands made from special materials.

In order to meet the specific requirements of our customers' projects, we offer wire strands and wire ropes with special treatments. These can be swaged / hammered, purified / cleaned or greased.

Material: Stainless steel AISI 301, tungsten

Construction: 1 x 7

Treatment: swaged

Diameter ø: from 0,20 to 0,39 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,28 | 75 | 0,45 | CG0070280HUG | LI000151 |

| 0,35 | 115 | 0,60 | CG0070350HUG | LI000155 |

| 0,39 | 140 | 0,76 | CG0070390HUG | LI000159 |

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | Colour | Item No. |

|---|---|---|---|---|

| 0,20 | 65 | 0,5 | black | LI000465 |

| 0,22 | 85 | 0,61 | black | on request |

| Other diameters are possible on request. Contact us for more information. | ||||

Material: Tungsten

Construction: 6 x 7 - WSC

Treatment: swaged / hammered

Diameter ø: von 0,20 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | Colour | Item No. |

|---|---|---|---|---|

| 0,2 | 65 | 0,45 | black | on request |

| Other diameters are possible on request. Contact us for more information. | ||||

Material: Tungsten

Construction: 8 x 19 + 7 x 7

Treatment: swaged / hammered

Diameter ø: von 0,45 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | Colour | Item No. |

|---|---|---|---|---|

| 0,45 | 285 | 1,85 | black | on request |

| Other diameters are possible on request. Contact us for more information. | ||||

Material: Tungsten

Construction: 8 x 19 + 7 x 7

Treatment: swaged / hammered

Diameter ø: von 0,50 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | Colour | Item No. |

|---|---|---|---|---|

| 0,5 | 300 | 2,46 | black | SE000633 |

| Other diameters are possible on request. Contact us for more information. | ||||

Material: Stainless steel AISI 316 or AISI 301 (spring steel)

Construction: 1 x 7

Treatment: purified

Diameter ø: from 0,09 to 0,75 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,09 | 6,9 | 0,040 | CG007009UG | LI000144 |

| 0,12 | 13,3 | 0,073 | CG007012UG | LI000145 |

| 0,15 | 20,0 | 0,113 | CG007015UG | LI000146 |

| 0,18 | 30 | 0,163 | CG007018UG | LI000147 |

| 0,21 | 41 | 0,210 | CG007021UG | LI000148 |

| 0,24 | 53 | 0,280 | CG007024UG | LI000149 |

| 0,27 | 70 | 0,360 | CG007027UG | LI000150 |

| 0,30 | 85 | 0,440 | CG007030UG | LI000152 |

| 0,33 | 100 | 0,540 | CG007033UG | LI000154 |

| 0,36 | 120 | 0,640 | CG007036UG | LI000157 |

| 0,39 | 140 | 0,750 | CG007039UG | LI000160 |

| 0,45 | 200 | 1,000 | CG007045UG | LI000162 |

| 0,51 | 280 | 1,250 | CG007051UG | LI000163 |

| 0,57 | 350 | 1,600 | CG007057UG | LI000164 |

| 0,60 | 400 | 1,800 | CG007060UG | LI000165 |

| 0,69 | 520 | 2,400 | CG007069UG | LI000166 |

| 0,75 | 600 | 2,800 | CG007075UG | LI000167 |

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,31 | 85 | 0,45 | CG0070310UG | LI000153 |

| 0,38 | 130 | 0,60 | CG0070380UG | LI000158 |

| 0,42 | 156 | 0,76 | CG0070420UG | LI000161 |

Material: Stainless steel AISI 316 or AISI 301 (spring steel)

Construction: 1 x 19

Treatment: purified

Diameter ø: from 0,15 to 1,00 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,15 | 25 | 0,110 | CG019015UG | LI000168 |

| 0,20 | 44 | 0,200 | CG019020UG | LI000169 |

| 0,25 | 69 | 0,300 | CG019025UG | LI000170 |

| 0,30 | 98 | 0,440 | CG019030UG | LI000171 |

| 0,35 | 135 | 0,600 | CG019035UG | LI000172 |

| 0,40 | 177 | 0,780 | CG019040UG | LI000173 |

| 0,45 | 224 | 0,970 | CG019045UG | LI000174 |

| 0,50 | 275 | 1,200 | CG019050UG | LI000176 |

| 0,55 | 330 | 1,450 | CG019055UG | LI000177 |

| 0,60 | 392 | 1,750 | CG019060UG | LI000179 |

| 0,65 | 461 | 2,070 | CG019065UG | LI000180 |

| 0,75 | 618 | 2,760 | CG019075UG | LI000181 |

| 0,85 | 795 | 3,500 | CG019085UG | LI000182 |

| 1,00 | 1079 | 4,900 | CG019100UG | LI000184 |

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,50 | 270 | 1,10 | CG0190500UG | LI000175 |

| 0,60 | 400 | 1,58 | CG0190600UG | LI000178 |

| 0,90 | 930 | 3,50 | CG0190900UG | LI000183 |

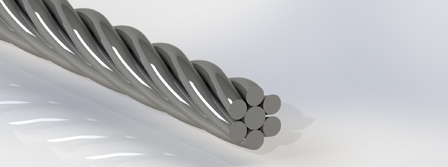

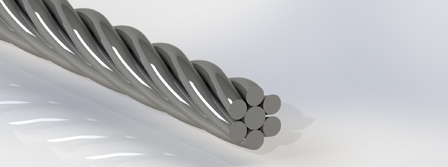

Material: Stainless steel AISI 316 or AISI 301 (spring steel)

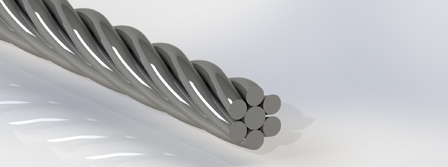

Construction: 6 x 7 - WSC

Core: steel

Treatment: purified

Diameter ø: from 0,12 to 1,20 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,12 | 10 | 0,060 | CG077012UG | SE000306 |

| 0,18 | 20 | 0,130 | CG077018UG | SE000307 |

| 0,27 | 54 | 0,290 | CG077027UG | SE000308 |

| 0,36 | 96 | 0,520 | CG077036UG | SE000309 |

| 0,45 | 151 | 0,800 | CG077045UG | SE000310 |

| 0,54 | 235 | 1,200 | CG077054UG | SE000311 |

| 0,63 | 293 | 1,600 | CG077063UG | SE000312 |

| 0,72 | 422 | 2,100 | CG0770722UG⁵ | SE000313 |

| 0,81 | 530 | 2,600 | CG077081UG⁵ | SE000234 |

| 0,90 | 647 | 3,200 | CG077090UG | on request |

| 1,00 | 785 | 3,900 | CG077100UG | SE000316 |

| 1,20 | 1075 | 5,000 | CG077120UG | SE000318 |

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,90 | 705 | 3,25 | CG0770900UG | SE000315 |

| 1,00 | 950 | 4,20 | CG0770100UG | SE000305 |

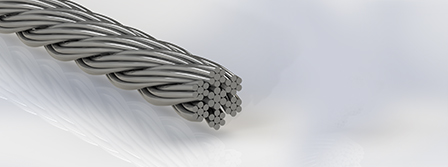

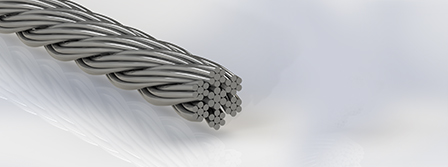

Material: Stainless steel AISI 316

Construction: 6 x 19 - WSC

Core: steel

Treatment: purified

Diameter ø: from 0,45 to 1,20 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,45 | 145 | 0,810 | CG719045UG | SE000319 |

| 0,60 | 270 | 1,440 | CG719060UG | SE000320 |

| 0,75 | 417,0 | 2,100 | CG719075UG | SE000321 |

| 0,90 | 613 | 3,500 | CG719090UG | SE000322 |

| 1,00 | 765 | 4,400 | CG719100UG | SE000323 |

| 1,20 | 976 | 5,600 | CG719120UG | SE000324 |

Material: Stainless steel Nitinol

Construction: 1 x 7

Diameter ø: 0,36 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 0,36 | 80 | 0,56 | CG007036NUG | LI000156 |

Material: Stainless Steel Nitinol

Construction: 6 x 7 - WSC

Core: steel

Diameter ø: 1,08 mm

| Nom. Dia in mm | Min. break. Load in N | Weight in kg/1000 m | old Item No. | new Item No. |

|---|---|---|---|---|

| 1,08 | 500 | 3,92 | CG077108NUG | SE000317 |

⁵ Only available in AISI 304

Material 1.4310: tensile strength 2160 N/mm²

Material 1.4401: tensile strength 1770 N/mm²

Material Nitinol: tensile strength 1000 N/mm²

Other lengths of lay according agreement.

Various other materials on request – e.g. copper, gold, silver, monel®, inconel®, hastelloy®, titanium®, incoloy®

High-quality strands and ropes are indispensable in medical technology. The highest demands are placed not only on reliable function, which is guaranteed by special materials such as tungsten or nitinol, but also on purity. We offer tailor-made solutions for the special requirements of medical technology. Our strands and ropes are subjected to an extensive cleaning process. We support our customers in the medical technology sector from conception to series production in accordance with their individual requirements. Our highly qualified employees are on hand to advise you with their medical technology expertise.

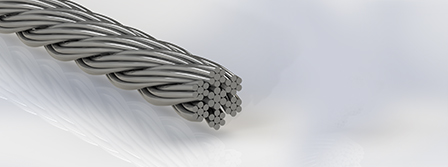

Assembled, purified wire ropes

The compaction or hammering of ropes and strands is a mechanical process that serves to smooth the surface and at the same time reduce the cross-section of the strand or rope. This does not reduce the breaking strength of the rope, but increases its stiffness, which results in less elongation. Compaction makes the dimensions smaller, which makes our fine ropes particularly suitable for use in the tightest installation spaces.

Compacted ropes are used wherever lower elongation and higher rigidity are required. The special processing of the strands gives them the so-called springy effect. This describes how quickly the strand springs back into its original shape. This makes the strand more resistant to external influences and ensures a high level of safety in use.

Left: Strand 1x7 Right: Strand 1x7 hammered / swaged

Greasing steel wire ropes is necessary in environments where the ropes are exposed to frequent bending cycles. This internal lubrication of the wires reduces the friction between the wires and reduces wear. This leads to a longer service life of the rope. During the greasing process, oil is introduced into the rope during stranding. This built-in lubrication thus reaches every single wire of the rope. If steel ropes and strands are lubricated, they are particularly durable and resistant when using pulleys. The ropes remain supple and have a high degree of flexibility.