If wire ropes are guided via pulleys, the service life can be optimized by selecting the right deflection pulley and the appropriate rope construction. Wire ropes made of tungsten can be used to achieve a smaller guide pulley in the application or a longer service life with the same pulley size.

These factors can have a positive or negative effect on the service life of the rope used:

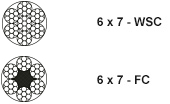

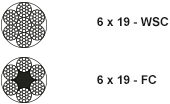

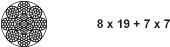

The ratio between groove diameter and rope diameter should be chosen according to the rope construction:

| Wire rope diameter | Bearing level | Recommended pulley type | ||||

|---|---|---|---|---|---|---|

| high | medium | low | ||||

| up to 3 mm | X | SP pulley with closed ball bearing |  | |||

| up to 3 mm | X | UP pulley with ball bearing |  | |||

| up to 3 mm | X | MP pulley with plain bearing |  | |||

| up to 3 mm | X | BP pulley without bearing |  | |||

| up to 8 mm | X | LP pulley with needle bearing |  | |||

| up to 8 mm | X | LP pulley with plain bearing |  | |||

| up to 8 mm | X | LP pulley without bearing |  | |||

In addition to choosing the correct pulley bearing, the selection of the appropriate groove diameter for the wire rope plays an important role. The following matrix will help you to find the right pulley for your application:

| Rope construction | Groove diameter in mm in mm |

|---|---|

| 42 x Rope diameter (uncoated) |

| 25 x Rope diameter (uncoated) |

| 16 x Rope diameter (uncoated) |

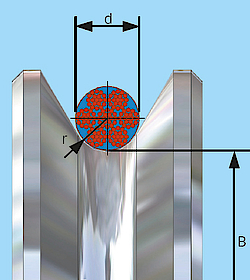

B = Groove diameter

d = Wire rope diameter incl. coating

r = Groove radius= 0,53 x d

The service life of our tungsten cable can be up to 5 times longer than that of a 1.4401/AISI316 stainless steel rope of the same design. Compared to a stainless steel rope of the same design, a smaller pulley can be used for the same service life when using a tungsten rope. This enables a smaller and more compact (slimmer) construction.