As a manufacturer and supplier of custom bowden cables and push-pull control cables with decades of experience, we assemble your bowden cable to suit your application.

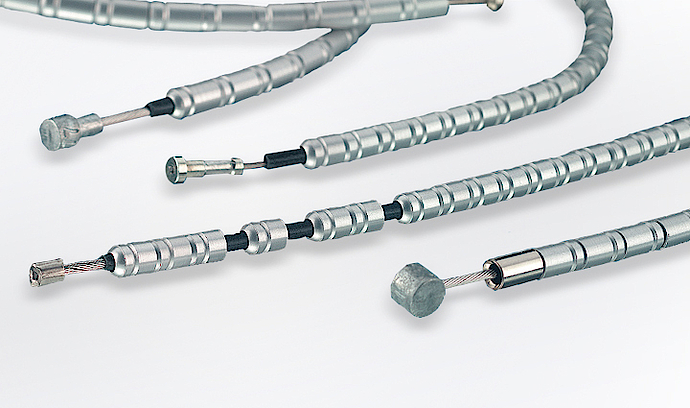

Our bowden cables consist of a pressure-resistant spiral sheath with one of our assembled steel wire ropes running inside. In addition, a flexible POM inner tube can be inserted between the spiral sheath and the steel wire rope to increase efficiency.

With a wide range of components in stock and our own rope factory and assembly facilities, we can manufacture your individual bowden cable or push-pull control cable to your requirements. As a manufacturer and supplier, we can ensure a variety of functions by selecting the right components, we can advise you on the selection of the most suitable components.

Our customised micro bowden cables are used in a variety of industries. We develop customised solutions for mechanical engineering, precision mechanics, robotics, automation systems, automotive industry, gardening tools technology and numerous others.

A bowden cable is made up of several parts. The bowden cable assembly starts with a sleeve and a bowden cable core. The core is made from high quality steel wire. The bowden control cables steel or stainless steel sleeves and other components can be assembled individually. The numerous standard components allow a wide range of variation possibilities. Create your own bowden cable.

Our own electrical cable assembly produces suitable bowden cable solutions according to your requirements.

With a fully automatic cable assembly, we are able to process standard crimp contacts.

The assembly of individual conductors creates cable harnesses through which signals and working currents can be transmitted.

In addition to cable assembly, we also offer ready-to-install cable harnesses for the manufacture of ready-to-install electric bowden cables.

The following examples give you an insight into the extensive variation options. We are able to manufacture customized bowden cable for your application.

Konkavex sytem bowden cables offer an absolutely pressure resistant casing. This results in a much higher efficiency compared to a conventional bowden cable. The basic elements are threaded together on a fluoropolymer liner. This liner serves as an inner coating for the cable as well as a support for the basic elements. With their unique design the aligned basic elements form a bowden cable which is extremely flexible and highly pressure resistant at the same time. This system is suitable for cable Ø 1,2- 1,5 mm.

Difference between push pull control cable and bowden cable

Push-pull cables are used when both, forces in pulling and pushing directions are required for a mechanical control system. A push-pull cable transmits forces in the pull direction like a bowden cable, but can also transmit forces in the push direction at the same time. It is similar in construction to a bowden cable. Push-pull control cables can be custom made to suit the application.