Customised steel wire rope assemblies, design and manufacture of wire rope assemblies to meet your exact requirements is our core competence.

Wire ropes are assembled into custom steel wire rope assemblies for mounting. Depending on the installation situation, different wire ropes end fittings are required such as eyelets, threaded ends or balls. In addition to the numerous standard end sleeves in stock, we also develop customised solutions that precisely meet your specifications and requirements. In our cable assembly department, wire rope ends are applied to our micro wire ropes by swaging or die-casting. Safe and automated processes ensure our high quality standards. Our cable assemblies are quick and easy to install. You save time and money.

Do you need technical support regarding of rope construction, rope diameter, material or wire rope end fittings / end terminations?

Benefit from our large standard portfolio of end fittings. The large number of standard end fittings and our high level of vertical integration means that we have solutions for a wide range of rope diameters and constructions. The large number of standard rope components allows a wide range of variations. We manufacture your custom steel wire rope assemblies from different rope types, wire rope fittings and other components.

We realise your wire rope assemblies, quickly and flexibly.

Thanks to our extensive range of standard terminals / wire rope ends and our large modular system for a wide variety of rope diameters, we are able to offer customised made wire rope cables assemblies.

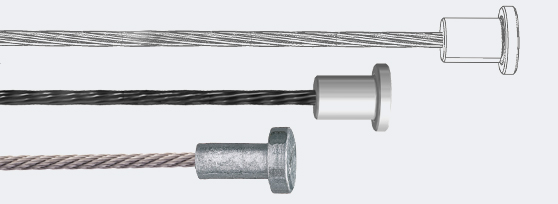

Wire rope end fittings / metal rope ends for assembled wire ropes The requirements for assembled wire ropes are very diverse. Thanks to our wide range of products, we are able to manufacture wire rope end fittings / metal rope ends to suit any specific requirement.

Individual special solutions

Whether steel wire rope, stainless steel wire rope, tungsten wire rope, e-rope, cleaned ropes or ready-to-install sets, we will find the right solution.

Due to ever more compact and lighter applications, installation space is becoming ever smaller. The wide range of possible assemblies and application options for our pre-assembled ropes offer safe, flexible solutions. Even if you do not have standard applications, we can develop special rope end terminations to meet your exact requirements.

Advantages of the wire rope ends:

A ready-made rope with a soft eye on both sides is very flexible and can be easily adapted and used to existing applications by varying the bolt diameter and loop length.

The size of the soft eye with thimble is specified and can be aligned accordingly in the middle. The soft eye with thimble distributes the load on the wire rope over a larger area, thus reducing the surface pressure and thus the wear on the wire rope.

With the eyelet, uniform fixing points are possible due to the given contour. This allows them to be permanently installed in existing applications.

Assembled ropes with balls can be used in even less space. Possible applications can be realized here that require linear force absorption and automatic centering of the rope.

A thread has the great advantage that it can be adjusted. The length can vary depending on the thread type and thread size. The tolerance can be compensated accordingly between the built-in ropes. This can also tighten the rope.

The shank end stop is a good choice if you have an application with a predetermined bore.

Our research and development department develops the right solutions for you.

In the area of development, CAD and construction, our technicians and engineers work out customized solutions for the respective application in dialogue with the customer. The high demands our customers place on the assembled TechnoCables are the benchmark for us. During development, prototypes are also produced for special requirements using innovative rapid prototyping. The initial samples are put through their paces by us. As soon as the product meets all requirements, series production begins.